Mini warp-weighted looms

In preparation for my CAMWS 2024 workshop on ancient Greek textile production, I set about trying to figure out the cheapest and easiest ways to make warp-weighted looms that were functional. The main goal was to be able to show learners how the warp-weighted loom actually worked, but of course it was an extra bonus for me to end up with a device that I could use.

I am very much indebted to the YouTube series by Sally Pointer that gives a step-by-step on how to create a warp-weighted loom. In creating my own, I essentially followed her instructions, but cutting out anything that required wood working tools (which I don't have). The result was a functional loom made out of sticks from my yard that cost me $0, being made entirely from things I already had at home.

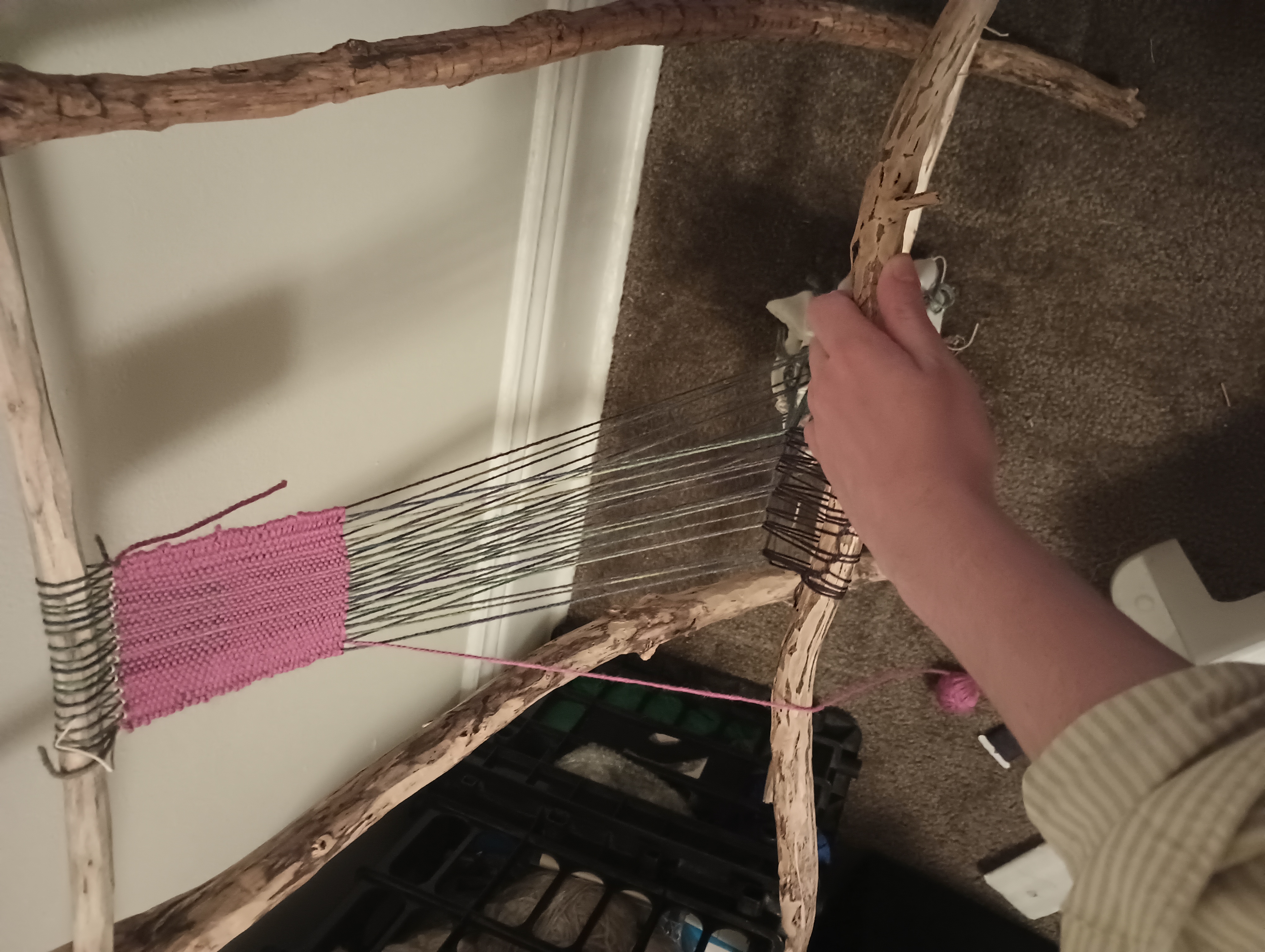

.jpg)

Here it is first warped up with some commercial yarn. The trickiest material for the loom is finding sticks that have a natural fork at the top so that the cloth bar can sit between them. The shed bar at the bottom is secured to the posts with string. The heddle bar has knit heddles, following Sally Pointer's instructions. For this first warp, I tied it directly to the cloth bar (as opposed to tablet weaving a heading band).

Loom weights

Of course for a warp-weighted loom I needed some loops weights. The loom weights tie on to the warp threads at the bottom and provide tension. I sewed myself some drawstring bags out of scrap fabric and loaded them up with whatever heavy things I had around the house (mostly small decorative painted rocks). I do need to find a day to go out and scavenge some plain gravel so I'm not using my own knick-knacks. I liked how they came out looking quite similar in shape to some of the Greek examples (e.g. below).

Weaving

To weave, you pass your shuttle back and forth through the shed (for a shuttle I was just using a ball of yarn, here). One shed is created by the angle of the loom leaning against the wall, with some of the warp threads hanging straight down, and others pulled away by their draping over the shed bar. To change shed, I pulled out the heddle bar and the knit heddles pulled forward the warp threads that were behind.

I now do have a weaving sword (used to beat the new thread in place), but for this first project I used a regular old fork to poke the new thread flush to the old, which worked quite well.

I have tried to tablet weave a starting band and warp up the loom with some thread that I spun myself. Unfortunately, so far I have not managed to make it work. The threads stick to each other too much and abrade eachother until they break. But I will keep trying with more oil/different techniques.

Mini mini loom

I continued my workshop prep with a quest to figure out if I could make a much smaller model that was still functional to enough of a degree that it could demonstrate how eactly the sheds and heddles worked. This proved to be a bit of a challenge in ways I hadn't anticipated. It turns out the weight is very important to a warp-weighted loom. Not just the weight of the loom-weights, but also the weight of the loom itself. The weight is what keeps the loom securely leaning against the wall and stuck in place as you pull the heddle bar to change the shed.

My mini mini loom does not lean against a wall, but instead has a full frame so that it can stand on its own. It is also glued to a base to help keep it from collapsing. I had to both glue the dowels together and secure them by tying them together with twine, or the structure proved quite delicate. The weights I have on it right now are also not as heavy as I would like, but it's hard to find things that are very small and quite heavy. Still, I think the mini mini loom is quite an adorable model and it can be woven on.

.jpg)

Circe at her loom :3

.jpg)

Above, my weaving sword purchased from TheDancingGoats on Etsy, and some tablet weaving cards I made from a cereal box.